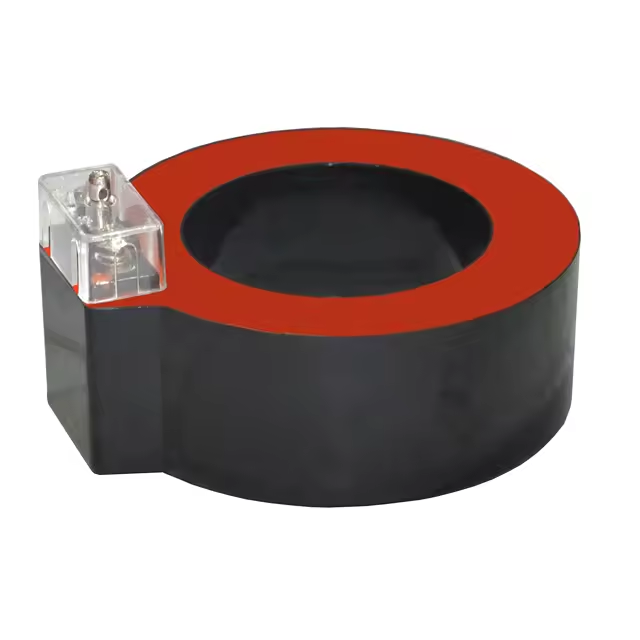

Application:

Suitable for indoor medium and high voltage electrical insulation parts. Such as dry-type transformers, transformers, insulators, supports, bushings, and switches.

Characteristics:

Very low viscosity, easy defoaming, good penetration; Excellent mechanical and electrical properties, low localized discharge; Excellent heat dissipation, high resistance to cracking; Low sediment.

Properties before curing:

| Appearance | Component A | Red viscous liquid |

| Component B | Off-white viscous liquid | |

| Density(25℃, g/cm³) | Component A | 1.52-1.62 |

| Component B | 1.72-1.83 | |

| Viscosity (25℃, mPa.s) | Component A | 9-16 |

| Component B | 15-25 |

Properties after curing:

| Tensile Strength (N/mm2) | 50-70 |

| Elongation at break (%) | 1.8-2.5 |

| Bending Strength (Mpa) | 105-125 |

| Surface Strain (%) | 1.5-1.7 |

| Fracture Ratio (J/m2) | 470-550 |

| Glass Transition Temperature (℃) | 70-85 |

| Linear Expansion Coefficient(ppm/k, lower than the average of Tg ) | 38-47 |

| Water Absorption(%, 100℃/24h) | ≤0.5 |

| Thermal Conductivity (W/mK) | 0.8-1.0 |

| Insulation Strength (KV/mm) | 22-28 |

| Dielectric Constant (50Hz) | ≤3.8 |

| Volume Resistivity (Ω/cm) | ≥1.0×1016 |

I. Mixing Ratio:

100:100

II. Pre-drying:

A, B material 60℃-65 ℃/4-5h

Pre-mixing and vacuum defoaming (for instantaneous static mixing process):

A component vacuum stirring defoaming 70 ~ 75℃ /1-2h, vacuum 50-200Pa

B component vacuum stirring defoaming 50 ~ 60℃ /1-2h, vacuum 50-200Pa

IV. Mixing and stirring:

63℃-67℃/30-45min, vacuum degree 50-200Pa

V. Mould pre-drying:

100-110℃/4-5h

VI. Casting room:

75℃ – 80℃ vacuum degree 50-300Pa workpiece temperature 75-80℃

VII. Pouring:

Pouring time control in 1.5 ~2 hours or less (from the beginning of mixing time), pay attention to the flow rate control, about 1.5kg/min, observe the bubbles, due to exothermic reaction of mixing materials, the final mixing tank temperature control at 60℃-65℃ or less.

After pouring, at 75℃ -80℃, vacuum 50-200Pa pouring chamber straight air pressure 30-45 minutes after leaving the tank into the curing process.

VIII. Curing process:

80℃/6H + 100℃/4H + 130℃/6H

Attention:

1. Flow control is generally manually operated, according to the size of the package of the flow rate of strict control, generally controlled to about 1.5 kg/min, to avoid rabbit bubble deposition.

2. The vacuum degree of the casting tank should be greater than the vacuum degree of the mixing tank by about 50Pa.

3. According to the seasonal changes, the temperature of the workpiece should be controlled to prevent cracking.

4. Workpiece out of the tank should be done quickly after the cleaning process

5. Observe the workpiece curing liquid level changes, timely replenishment of materials

6. Simple moulds should pay attention to error control.

7. Suggest using a high-quality mould-releasing agent to ensure the effect of mould release.

Packing:

Component A: 25kg/barrel, Component B: 25kg/barrel.

Storage condition:

The product should be sealed in the original packaging container and stored in a dry and ventilated place. In the environment of 18-40℃, the shelf life is 6 months. If shelf life is exceeded, analysis is required to determine whether it is still valid.

Due to storage conditions, a small amount of precipitation may occur during storage, which is normal, and can be used normally after mixing.