Casting & Potting Resins Area

The resins can enhance the integrity of electronic devices, improve their resistance to external impact and vibration, prevent direct exposure of components and circuits, and provide waterproof, moisture-proof, dust-proof, thermal conductivity, confidentiality, corrosion resistance, and temperature resistance properties.

For General Types

They include three types: epoxy, polyurethane, and silicone, predominantly with double-component. They can be categorized into two types based on the curing method: ambient curing and heat curing. They can also be divided into various types based on their performance, such as flame retardant, thermal conductive, and low modulus. Rongtai Technology is a professional epoxy resin supplier and wholesaler for electric insulating.

| Item No. | Base Resin | Unique Characteristics | Viscosity @25℃ mPa·s | Mix Ratio | Cure Schedule | Flame retardant Grade | Thermal Conductivity(W/m·K) | Hardness | Thermal Class |

| SW-729-9 | Epoxy Resin | Medium temperature curing, excellent liquidity, good flame retardant, high strength | 2000-8000 | 100:25~35 | 85℃@6h/105℃@2h | V-0 | 0.4-0.6 | 80-90D | 130℃ |

| SW-729-11 | Epoxy Resin | Double-filled medium temperature cure, excellent liquidity, flame retardant, high strength, low CTE(Coefficient of Thermal Expansion) | 25000-45000 | 100:100 | 85℃@6h/105℃@2h | V-0 | 0.6 | 90D | 155℃ |

| SW-729-8 | Epoxy Resin | Medium viscosity, fast curing, good adhesion, anti-crack | 150000-250000 | 100:18~20 | 100℃@0.5h/23℃@12h | V-0 | 0.6 | 80D | 155℃ |

| SW-729-7 | Epoxy Resin | Low viscosity, anti-crack, low shrinkage, shiny surface | 8000-30000 | 100:20~25 | 23℃@12h/80℃@1h | V-0 | 0.5 | 80D | 155℃ |

| SW-729-7 Extra Clear | Epoxy Resin | Non-filled and self-drying products, good for water pump cable sealing | 2000-3000 | 100:30~40 | 23℃@2h | —— | —— | 75D | 130℃ |

| SW-729-35 | Epoxy Resin | Non-filled and self-drying product, high stiffness, good for water pump cable sealing | 2300-3300 | 100:45~50 | 23℃@2h | —— | —— | 80D | 130℃ |

| SW-729-6 | Epoxy Resin | High cost-effectiveness | 8000-20000 | 100:15 | 23℃@12h/80℃@1h | —— | 0.5 | 70D | 130℃ |

| SW-729-6 Enhanced | Epoxy Resin | Filling aluminum casting water pumps | 15000-21000 | 100:10 | 23℃@12h | —— | 0.5 | 70D | 130℃ |

| Epoxy Resin | Potting shielded pump | 5500-7500 | 100:17 | 23℃@12h/80℃@1h | V-0 | 0.7 | 75D | 155℃ | |

| SW-729-42 | Epoxy Resin | High strength, low curing shrinkage, low CTE(Coefficient of Thermal Expansion) | 40000-90000 | 100:10 | 80℃@2h+120℃@2h | V-0 | 0.9 | 85D | 180℃ |

| SW-729-47 | Epoxy Resin | High thermal conductivity, medium viscosity, excellent liquidity, fast curing | 100000-200000 | 100:7 | 80℃@2h | V-0 | 1.3 | 90D | 155℃ |

| SW-729-48 | Epoxy Resin | Addition system, high thermal conductivity, good liquidity | 30000-70000 | 100:7 | 80℃@2h | V-0 | 1.5 | 90D | 155℃ |

| SW-729-4DZ | Epoxy Resin | Excellent liquidity, high thermal conductivity, flame retardant, anti-crack | 6000-35000 | 100:13 | 23℃@12h/100℃@1h | V-0 | 0.9 | 80D | 155℃ |

| SW-729-5 | Epoxy Resin | Excellent liquidity, fast curing, good flexibility, high hardness, low modulus | 8000-12000 | 100:16 | 23℃@12h/100℃@1h | V-0 | 0.7 | 75D | 155℃ |

| SW-729-4 | Epoxy Resin | Excellent processability, medium curing speed | 8000-12000 | 100:18 | 80℃/2h | —— | 0.5 | 80D | 130℃ |

| SW-727-9 | Silicone | Addition system, low curing shrinkage | 2000 | 100:100 | 23℃@6h/80℃@10min | V-0 | 0.65 | 60A | 200℃ |

| SW-727-11 | Silicone | Addition system, low cost | 2500 | 100:100 | 23℃@6h/80℃@10min | V-0 | 0.75 | 60A | 200℃ |

| SW-727-12 | Silicone | Addition system, high flow, potting for small gaps | 1000 | 100:100 | 23℃@10h/80℃@30min | V-1 | 0.43 | 68A | 200℃ |

| SW-727-15 | Silicone | Addition system, red color, high strength, good heat resistance | 2000 | 100:100 | 23℃@6h/80℃@10min | V-0 | 0.55 | 60A | 250℃ |

| SW-727-8 | Silicone | Addition system, good thermal conductivity, good liquidity | 2900 | 100:100 | 23℃@6h/80℃@10min | V-0 | 1 | 60A | 200℃ |

| SW-727-7 | Silicone | Addition system, high thermal conductivity, good liquidity | 5700 | 100:100 | 23℃@6h/80℃@10min | V-0 | 1.6 | 67A | 200℃ |

| SW-727-32 | Silicone | Addition system, high thermal conductivity, good liquidity | 8000 | 100:100 | 23℃@6h/80℃@10min | V-0 | 2 | 70A | 200℃ |

| SW-727-33 | Silicone | Addition system, high thermal conductivity, good liquidity | 15000 | 100:100 | 23℃@6h/80℃@10min | V-0 | 3 | 78A | 200℃ |

| SW-727-T | Silicone | Addition system, transparent | 1000 | 100:100 | 23℃@6h/80℃@10min | —— | —— | 30A | 200℃ |

| SW-727-T5 | Silicone | Addition system, transparent, strong bond strength | 500 | 100:100 | 60℃@1h/80℃@30min | —— | —— | 18A | 200℃ |

| SW-727-T51 | Silicone | Addition system, transparent, Gel | 900 | 100:100 | 23℃@6h/80℃@10min | —— | —— | 190Cone penetration | 200℃ |

| SW-727-4 | Silicone | Condensation system, easy mixing ratio, good adhesion | 900 | 100:20 | 23℃@24h | —— | 0.55 | 48A | 200℃ |

| SW-727-3 | Silicone | Condensation system, good adhesion | 900 | 100:10 | 23℃@24h | —— | 0.55 | 48A | 200℃ |

| SW-727-2 | Silicone | Condensation system, flame retardant, matte color available | 900 | 100:10 | 23℃@24h | V-1 | 0.4 | 31A | 200℃ |

| SW-727-T6 | Silicone | Condensation system, transparent, good adhesion | 600 | 100:10 | 23℃@24h | 30A | 200℃ | ||

| SW-728-53 | Polyurethane | Soft, low-temperature resistance, good adhesion | 1300 | 100/30 | 23℃@12h/80℃@1h | V-0 | 0.4 | 50A | 130℃ |

| SW-728-271 | Polyurethane | Low viscosity, vibrate resistance, shiny surface | 600 | 100/20 | 23℃@12h/80℃@1h | V-0 | 0.5 | 75A | 130℃ |

| SW-728-B3 | Polyurethane | Flexible, vibrate resistance, shiny surface | 1100 | 100/17 | 23℃@12h/60℃@4h | V-0 | 0.6 | 80A | 130℃ |

| SW-728-32 | Polyurethane | good adhesion, vibrate resistance, fast curing | 1000 | 100/25 | 23℃@12h/80℃@1h | V-0 | 0.6 | 90A | 130℃ |

| SW-728-13 | Polyurethane | Extra low viscosity, vibrate resistance, shiny surface | 500 | 100/33 | 23℃@12h/80℃@1h | V-0 | 0.4 | 50D | 130℃ |

| SW-728-36 | Polyurethane | high hardness, low shrinkage, vibrate resistance, good water resistance | 1200 | 100/20 | 23℃@12h/80℃@1h | V-0 | 0.65 | 70D | 130℃ |

| SW-728-39 | Polyurethane | High thermal conductivity, strong water resistance, resistance to cold thermal shock | 2500 | 100/14 | 23℃@12h/80℃@1h | V-0 | 1 | 40D | 130℃ |

| SW-728-T2 | Polyurethane | Transparent, soft, low-temperature resistance, waterproof | 350 | 100/20 | 23℃@12h/80℃@1h | V-0 | —— | 30A | 130 |

For Rotating Motors

They are mainly epoxy resin-based, including some silicone-based potting products. They possess excellent flow-ability, high penetration, low shrinkage, resistance to thermal shocks, good thermal conductivity, and high heat resistance, which are suitable for potting various motors.

| Item No. | Base Resin | Unique Characteristics | Viscosity @25℃ mPa·s | Mix Ratio | Cure Schedule | Flame retardant grade | Thermal Conductivity(W/m·K) | Hardness | Thermal Class |

| SW-729-1E | Epoxy Resin | High thermal conductivity, high strength, anti-crack, heat resistance | 800-1500 @80℃ | 100:100 | 80℃ @5h+100℃@ 4h+130℃@6h | —— | 1.0 | 90D | 155℃ |

| SW-729-8 | Epoxy Resin | Medium viscosity, fast curing, good adhesion, anti-crack | 150000-250000 | 100:18~20 | 100℃@0.5h/23℃@12h | V-0 | 0.6 | 80D | 155℃ |

| SW-729-6 Enhanced | Epoxy Resin | Filling aluminum casting water pumps | 15000-21000 | 100:10 | 23℃@12h | —— | 0.5 | 70D | 130℃ |

| Epoxy Resin | Potting shielded pump | 5500-7500 | 100:17 | 23℃@12h/80℃@1h | V-0 | 0.7 | 75D | 155℃ | |

| SW-729-68 | Epoxy Resin | High strength, low curing shrinkage, low CTE(Coefficient of Thermal Expansion) | 40000-90000 | 100:10 | 80℃@2h+120℃@2h | V-0 | 0.9 | 85D | 180℃ |

| SW-729-63 | Epoxy Resin | High thermal conductivity, medium viscosity, excellent liquidity, fast curing | 100000-200000 | 100:7 | 80℃@2h | V-0 | 1.3 | 90D | 155℃ |

| SW-729-62 | Epoxy Resin | High thermal conductivity, medium viscosity, excellent liquidity, fast curing | 30000-70000 | 100:7 | 80℃@2h | V-0 | 1.5 | 90D | 155℃ |

| SW-729-4DZ | Epoxy Resin | Excellent liquidity, high thermal conductivity, flame retardant, anti-crack | 6000-35000 | 100:13 | 23℃@12h/100℃@1h | V-0 | 0.9 | 80D | 155℃ |

| SW-729-5 | Epoxy Resin | Excellent liquidity, fast curing, good flexibility, high hardness, low modulus | 8000-12000 | 100:16 | 23℃@12h/100℃@1h | V-0 | 0.7 | 75D | 155℃ |

| SW-729-4 | Epoxy Resin | Excellent processability, medium curing speed | 8000-12000 | 100:18 | 80℃/2h | —— | 0.5 | 80D | 130℃ |

| SW-529-8 | Epoxy Resin | Flame retardant, heat resistant, good resistance to cracking | 1000-2000 @60℃ | 100:9 | 80℃@2h+100℃@2h | V0 | 0.8 | 85D | 180℃ |

| SW-727-77 | Silicone | Addition system, high thermal conductivity, good liquidity | 15000 | 100:100 | 23℃@6h/80℃@10min | V-0 | 3 | 78A | 200℃ |

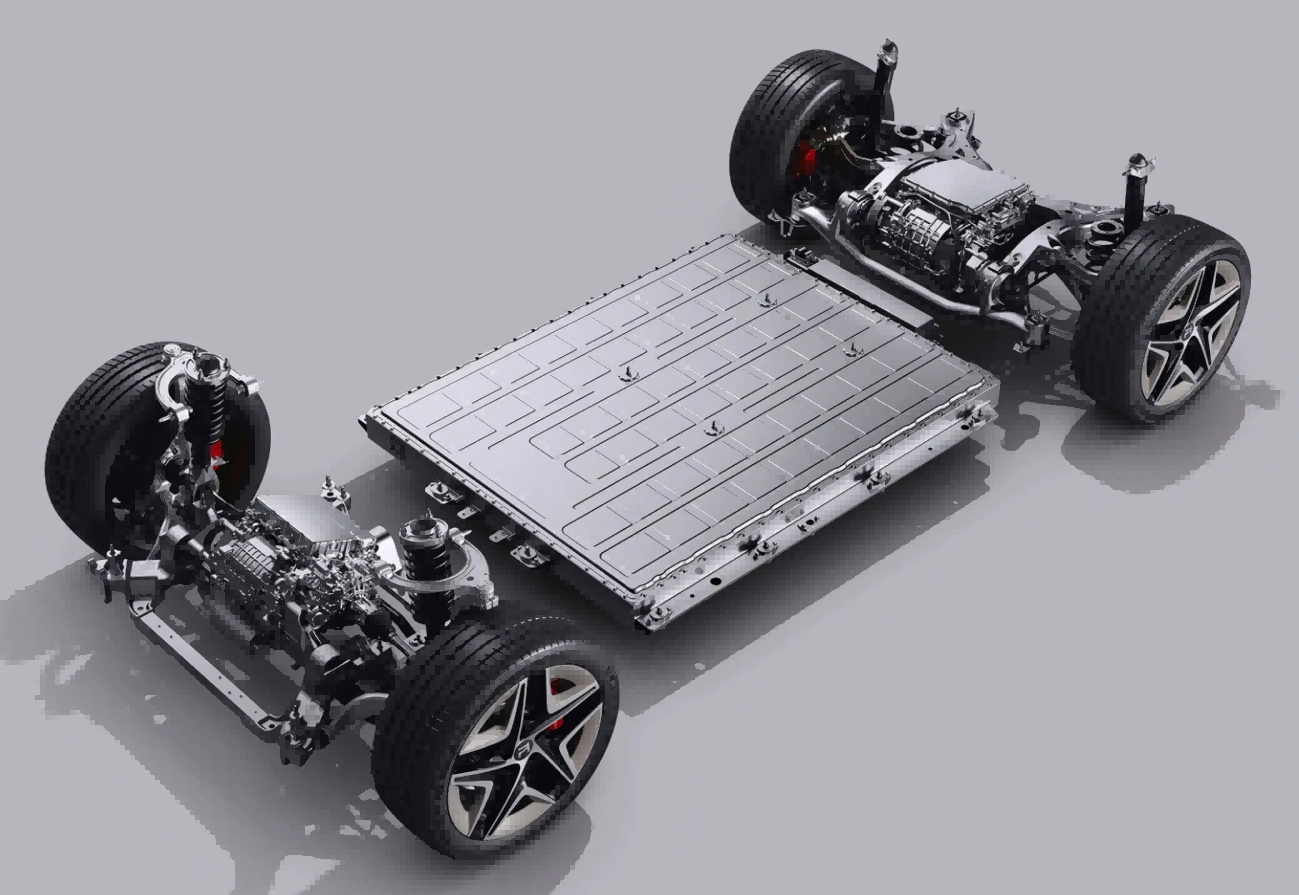

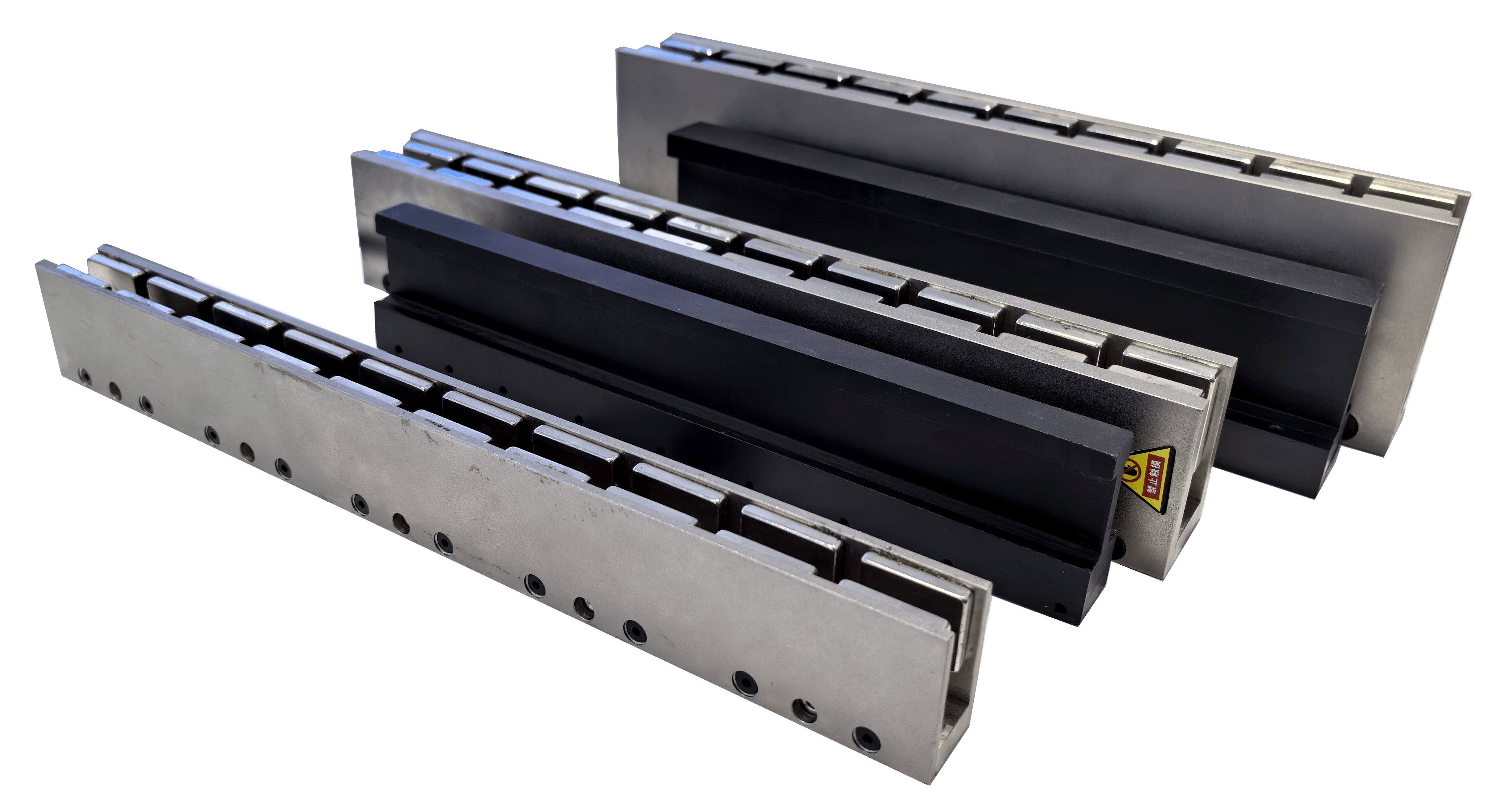

For Linear Motors

It has the characteristics of good fluidity, low shrinkage, low coefficient of linear expansion, resistance to cold and thermal shock, and high thermal conductivity. It is suitable for pouring and packaging various types of linear motors.

For Power Transformers

They cover the potting of small electronic components and the casting of large dry-type transformer coils. They have good flowability and excellent insulation performance and are especially characterized by low shrinkage and good crack resistance.

| Item No. | Base Resin | Unique Characteristics | Viscosity @25℃ mPa·s | Mix Ratio | Cure Schedule | Flame retardant Grade | Thermal Conductivity(W/m·K) | Hardness | Thermal Class |

| SW-729-D | Epoxy Resin | Vacuum cast resin, flexibility,anti-crack, easy to penetrate | 700-1200 @80℃ | 100:100 | 80℃ @5h+100℃@ 4h+130℃@6h | —— | 0.6 | 85D | 155℃ |

| SW-729-8 | Epoxy Resin | Medium viscosity, fast curing, good adhesion, anti-crack | 150000-250000 | 100:18~20 | 100℃@0.5h/23℃@12h | V-0 | 0.6 | 80D | 155℃ |

| SW-729-7 | Epoxy Resin | Low viscosity, anti-crack, low shrinkage, shiny surface | 8000-30000 | 100:20~25 | 23℃@12h/80℃@1h | V-0 | 0.5 | 80D | 155℃ |

| SW-729-75 | Epoxy Resin | Non-filled and self-drying product, high stiffness, good for water pump cable sealing | 2300-3300 | 100:45~50 | 23℃@2h | —— | —— | 80D | 130℃ |

| SW-729-6 Enhanced | Epoxy Resin | Filling aluminum casting water pumps | 15000-21000 | 100:10 | 23℃@12h | —— | 0.5 | 70D | 130℃ |

| Epoxy Resin | Potting shielded pump | 5500-7500 | 100:17 | 23℃@12h/80℃@1h | V-0 | 0.7 | 75D | 155℃ | |

| SW-729-68 | Epoxy Resin | High strength, low curing shrinkage, low CTE(Coefficient of Thermal Expansion) | 40000-90000 | 100:10 | 80℃@2h+120℃@2h | V-0 | 0.9 | 85D | 180℃ |

| SW-729-63 | Epoxy Resin | High thermal conductivity, medium viscosity, excellent liquidity, fast curing | 100000-200000 | 100:7 | 80℃@2h | V-0 | 1.3 | 90D | 155℃ |

| SW-729-62 | Epoxy Resin | High thermal conductivity, medium viscosity, excellent liquidity, fast curing | 30000-70000 | 100:7 | 80℃@2h | V-0 | 1.5 | 90D | 155℃ |

| SW-729-4DZ | Epoxy Resin | Excellent liquidity, high thermal conductivity, flame retardant, anti-crack | 6000-35000 | 100:13 | 23℃@12h/100℃@1h | V-0 | 0.9 | 80D | 155℃ |

| SW-729-5 | Epoxy Resin | Excellent liquidity, fast curing, good flexibility, high hardness, low modulus | 8000-12000 | 100:16 | 23℃@12h/100℃@1h | V-0 | 0.7 | 75D | 155℃ |

| SW-729-4 | Epoxy Resin | Excellent processability, medium curing speed | 8000-12000 | 100:18 | 80℃/2h | —— | 0.5 | 80D | 130℃ |

For Special Field