Features of Epoxy Resin Electronic Potting Adhesive:

There are many types of epoxy resin sealing adhesive in the sealing adhesive, with a wide range of applications, especially technical requirements. Therefore, curing can be divided into two types: room-temperature curing and heating curing. Both mechanical sealing and manual sealing can achieve the characteristics of protecting electrical components after solidification, especially with superior waterproof, moisture-proof, and anti-corrosion performance.

Characteristics:

Good insulation performance, physical properties, surface gloss, processability, and crack resistance.

Application:

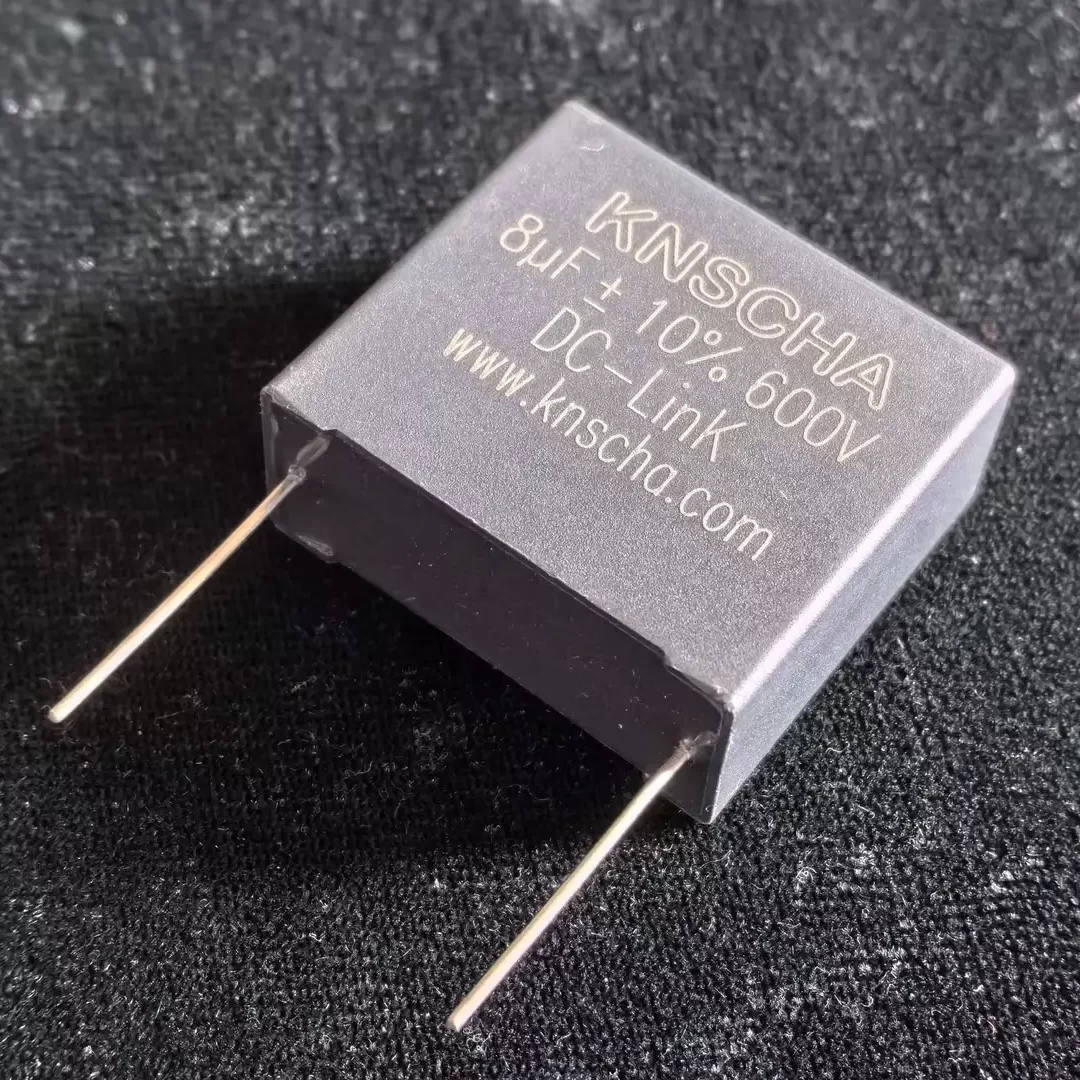

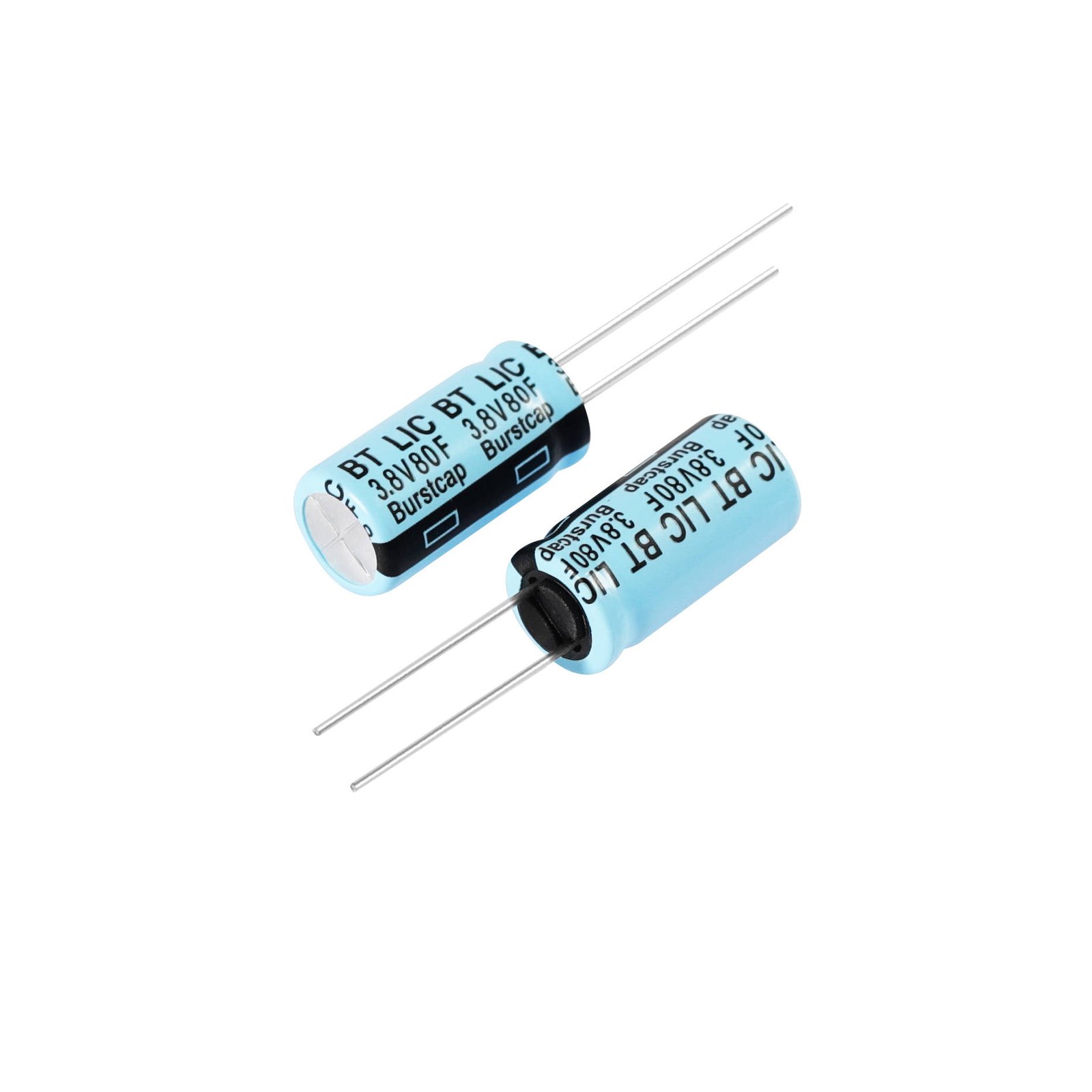

Suitable for insulation and waterproof packaging of electronic products such as capacitors, igniters, transformers, aquarium pumps, drive power supplies, sensors, etc.

Property before curing:

| Appearance | Component A | Black viscous liquid (Color-Tunable) |

| Component B | Brown liquid | |

| Density(25℃, g/cm³) | Component A | 1.70-1.85 |

| Component B | 1.03-1.12 | |

| Viscosity (40℃, mPa.s) | Component A | 1000-3500 |

| Component B | 5-35 |

Property after curing (25℃, 5-6 hours curing):

| Glass Transition Temperature (℃) | 45-75 |

| Linear Expansion Coefficient(ppm/k, lower than the average of Tg ) | 48-65 |

| Water Absorption(%, 100℃/24h) | ≤1.0 |

| Thermal Conductivity (W/mK) | 0.40-0.65 |

| Insulation Strength (KV/mm) | 15-21 |

| Dielectric Constant (50Hz) | ≤4.2 |

| Volume Resistivity (Ω/cm) | ≥1.0×1015 |

Mixing Ratio:

100:18-20

Packaging:

Component A: 30kg/barrel, Component B: 5kg/barrel.

Storage conditions:

The product should be sealed in its original packaging container and stored in a dry and ventilated place. In an environment of 18-40℃, the shelf life is 6 months. If the shelf life is exceeded, the analysis is required to determine whether it is still valid.

Due to storage conditions, this product may experience a small amount of precipitation during storage, which is a normal phenomenon. After stirring evenly, it can be used normally.