Key Attributes

| CAS No. | 61788-97-4 | Place of Origin | China |

| Main Raw Material | POLYURETHANE | Usage | Fiber & Garment, Packing, Transportation, Woodworking, Polyurethane Potting |

| Other Names | Polyurethane Potting Resin | MF | (C11H12O3)n |

| EINECS No. | other | Classification | Double Components Adhesives |

| Brand Name | pony resin | Model Number | SW-885AB |

| Type | Two Component Liquid Coating | Color | Black |

| Viscosity | A=9000±2000 B=200±50 | Density | A=1.17±0.05 B=0.95±0.03 |

| Mixing Ratio | A: B=5:1 | MOQ | 1kg |

| Shelf life | 12 Months/Quality Guarantee | Supply Ability | 10000 Ton/Tons per Day |

Products Description

Name | Electronic Components Epoxy Resin |

Material | Polyurethane Resin and Hardener |

Epoxy Resin and Hardener | Effective Resin Chemistries for the Protection of Electronic Components |

Color | Transparent/White/Black |

Advantage | Great bonding capability, fast wet out, good flexibility, low odor |

Delivery Time | 10-20 Days |

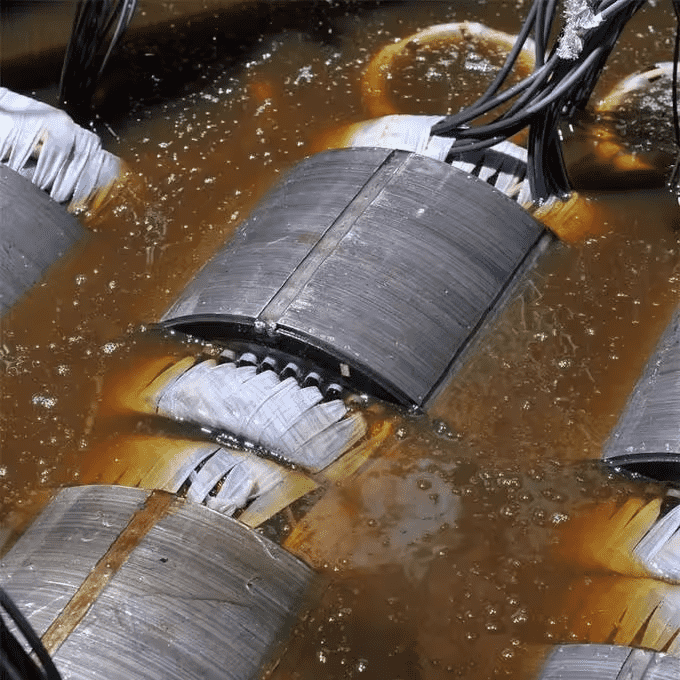

It’s designed for pouring and protecting Automobile parts and supplying physical strength to the elements, where excellent properties and exceptional thermal shock at elevated temperatures are required.

The electronic potting compound is a kind of two-component (5:1 mixing ratio) addition cure Epoxy with the characteristics of heat-conducting, low viscosity, inherent flame resistance, waterproofing, etc.

It can cure both at room temperature and heated temperature and the curing time can be accelerated by higher temperature.

PROPERTY | Part A | Part B |

Color (Appearance) | Black Viscous Liquid | Brown liquid |

Viscosity, cps, 25℃ | 30000~40000 | 100~200 |

Density (g/cm³) (GB/T 15223-1994) | 1.60~1.70 | 1.05~1.15 |

Mixture ratio (Weight Ratio) | A:B = 5:1 | |

Viscosity of mixture,4#rotor,cps , 25℃ | 2000~4000 | |

Operation time, mins, 25℃ | 30-50 | |

Cure condition | 25℃/4~6Hrs | |

Cured appearance | Black Elastomer | |

Hardness, Shore D | >80 | |

Thermal conductivity, W/K.T | 0.5 | |

Shear strength, Fe-Fe, MPa | >10 | |

dielectric loss angle tangent,1.2MHz | <0.01 | |

Volume resistance,DC 500V, Ω·CM | 1.1×1014 | |

Breakdown voltage,kV/mm,25℃ | >18 | |

Cure shrinkage,% | <2 | |

Dielectric constant(1 MHz) | 3.3±0.1 | |

Application temperature, ℃ | – 40 – 120 | |

Flame resistance ( UL-94) | V-0 | |

the A and B components according to the provisions of the quality ratio of mixing (see the table above

the mixing ratio), stir even after potting, The time available after mixing is shown in the table above.

More than the available time, glue viscosity will be high, and no longer suitable for perfusion. So each time

the amount of plastic should not be too much, otherwise, it will cause waste.

2. Curing: Cure conditions See table above. Curing speed and temperature-related, high-temperature

fast curing, winter temperature is low, curing time will be extended, a variety of plastic can be used

curing method, at 80 ℃ under the conditions of curing 2 to 3 hours. After the hardening of the

glue can be assembled, the test generally needs to cure 24 to 48 hours after the curing.

OPERATION PRECAUTION

1. Before using the A component of the compound must be in the original packaging to stir evenly (because the long-term placement may be precipitation, stirring even after use, does not affect performance).

2. Different seasons due to temperature changes in curing speed is normal, the winter temperature is low curing will be slower. Above all kinds of plastic can be used for heating curing methods.

3. Some of the A, and B components of the colloid in the low-temperature conditions may cause crystallization, and agglomeration, which is normal; before use it can be placed in the oven at 80 ℃ to melt, and then put to room temperature after use Does not affect its performance.

4. In the mixing process, pay attention to the inner wall of the container must be folded back to the mixing, to ensure the uniformity of plastic. Curing time is affected by temperature, winter can choose to use the winter formula

* Keep away from Children

* Avoid contact with eyes and skin. If contact with your skin, scrub first with soap water, or alcohol, then rinse with water. If contact with your eyes, rinse with plenty of water and seek medical treatment immediately.

* It is forbidden to build on the surface of the wet substrate.